CP-5000 is a two-component solvent-free epoxy floor paint. Nice appearance, dust &corrosion resistant and easy to clean. The flooring system can bond well with the solid base and has good abrasion and wearing resistance. Meanwhile, it has certain toughness, brittle-resistance and can stand a certain weight. The compressive strength and impact resistance ability is also excellent.

Advantages:

1. Smooth mirror-like surface

2. Seamless, non-dusty and easy to clean

3. Solvent-free and environmental

4. Corrosion-resistance dense surface

5. A large range of colors for choice

Where to Use:

It is mainly used for the non-dusty and non-bacteria areas like pharmaceutical factory, hospital, precision machinery, electronic factory, Garment/Knitting/Textile/Spinning/Denim/Yarn/Dyeing/Apparel Factory,etc.

Requirements for the base:

1. Concrete strength≥C25;

2. Flatness: the maximum altitude difference of

3. The moisture content of the base<4%

Technical Data:

Drying time:

Touch dry for walk: 24 hours (25℃)

Hard dry: 7 days (25℃)

Compressive strength (Mpa): ≧85

Impact resistance strength (Kg·cm): 65

Flexural strength (Mpa): ≧75

Adhesive force grade: 1

Shaw hardness (D): ≧80

Abrasion resistance(

Resistance to engine oil, diesel oil for 60 days: no change.

Resistance to 20% sulfuric acid for 20 days: no change

Resistance to 20% Sodium hydroxide for 30 days: no change

Resistance to toluene, ethanol for 60 days: no change

Service life: >8 years

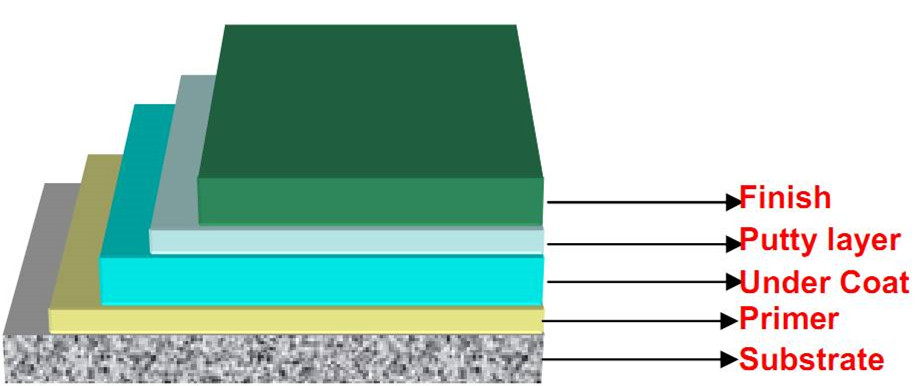

Recommended Coating System Consumption:

1st Coat: Epoxy Primer (Model:CP-30):

2nd Coat: Epoxy Undercoat (CP-MA):

3rd Coat: EpoxyTop coat (Model CP-5000): 0.8

Coating Instruction, click for details.

Chinese

Chinese English

English