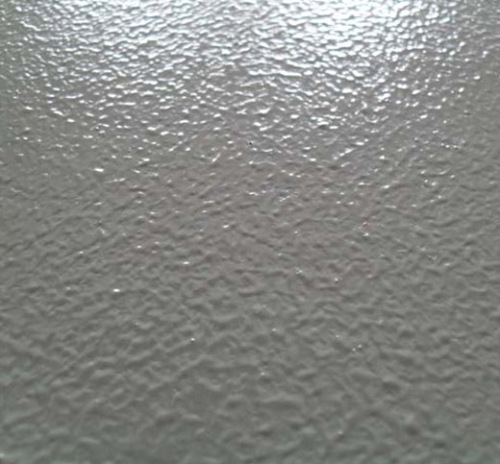

CP-ET is a two-component solvent based anti-slip epoxy finish. It can be applied in the cold and moist environment, especially in the wet and humid areas, for example foodstuff factory where anti-slip performance is necessary. The coating is a hard,wear-resistant wrinkle surface, but still easy to clean. Wide range of colors for your choice.

Advantages:

1. Nice appearance and dustproof.

2. Strong bonding with the base, low shrinkage, durable and wear-resistant.

3. Corrosion-resistant to the general chemicals.

4. Good anti-slip performance.

5. Bear moderate load.

Where to Use:

It is mainly used for concrete surface where has compression & wearing resistance and anti-dust and corrosion requirement, such as industry workshop, office, warehouse, foodstuff factory etc.

Requirements for the base:

1. Concrete strength≥C25;

2. Flatness: the maximum fall head between highest and lowest point <

3. Press polish of the concrete surface with cement mortar is recommended.

4. Water & damp proof treatment is suggested before application of leveling layer of the concrete.

Technical Data:

Drying time:

Touch dry: 6~8 hours (25℃) Hard dry: 7 days (25℃)

Compressive strength (Mpa): ≥80

Impact resistance strength (Kg·cm): ≥50

Flexural strength (Mpa): 40

Adhesive force grade: 1

Pencil Hardness (H): 3H

Abrasion resistance(

Resistance to engine oil, diesel oil for 60 days: no change.

Resistance to 50% sulfuric acid for 20 days: no change

Resistance to 25% Sodium hydroxide for 30 days: no change

Resistance to toluene, ethanol for 60 days: no change

Recommended Consumption:

Primer:

Putty layer: 0.2kg/square meter

Finish: 0.4kg/square meter

Quartz Powder: 0.4kg/square meter

For Application Instruction details and video of epoxy floor paint, Click here.

Chinese

Chinese English

English