1, Moisture Content Checking:

Method 1: pave transparent plastic film of 45*45cm onto the concrete floor, and seal the four sides with adhesive tape. Wait for 16 hours and check if there is any water bead inside the film or the concrete floor goes black. If so, it means the moisture content of the concrete floor is high, therefore it is not appropriate for epoxy installation.

Method 2: Professional moisture tester for instant test.

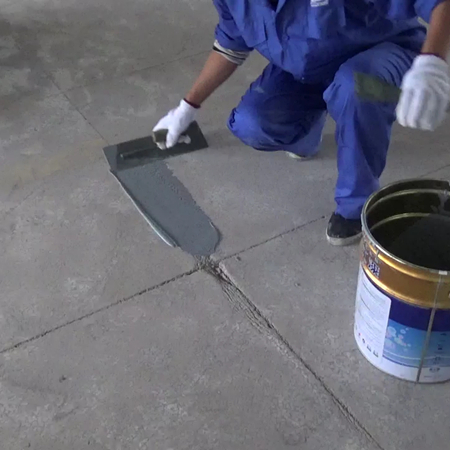

2,Hardness &Strength Testing:

Use spatula or iron nail to scrape the concrete floor in cross, watch if there’s any powder dust falling off,and obvious scratch. If the scratch is over 2mm deep, the hardness and strength is not good enough, so grinding is needed to improve hardness and strength.

3,Flatness Checking:

Put the 2m long running ruler onto the concrete floor, watch the gap size between ruler and floor. The maximum altitude difference should be below 3mm. If it’s over 3mm,the floor will needs to be grinded for leveling before epoxy.

4,Temperature and Humidity Checking

Put temperature and humidity instrument onto the concrete floor for about half hour, then you will get the practical data. The temperature should be above 10 centi-degree, and humidity should be below 85%.

Chinese

Chinese English

English