Application of Polyurethane Screed Flooring System

Application of Polyurethane Screed Flooring System

1,Substrate Shot Blasting and Grinding

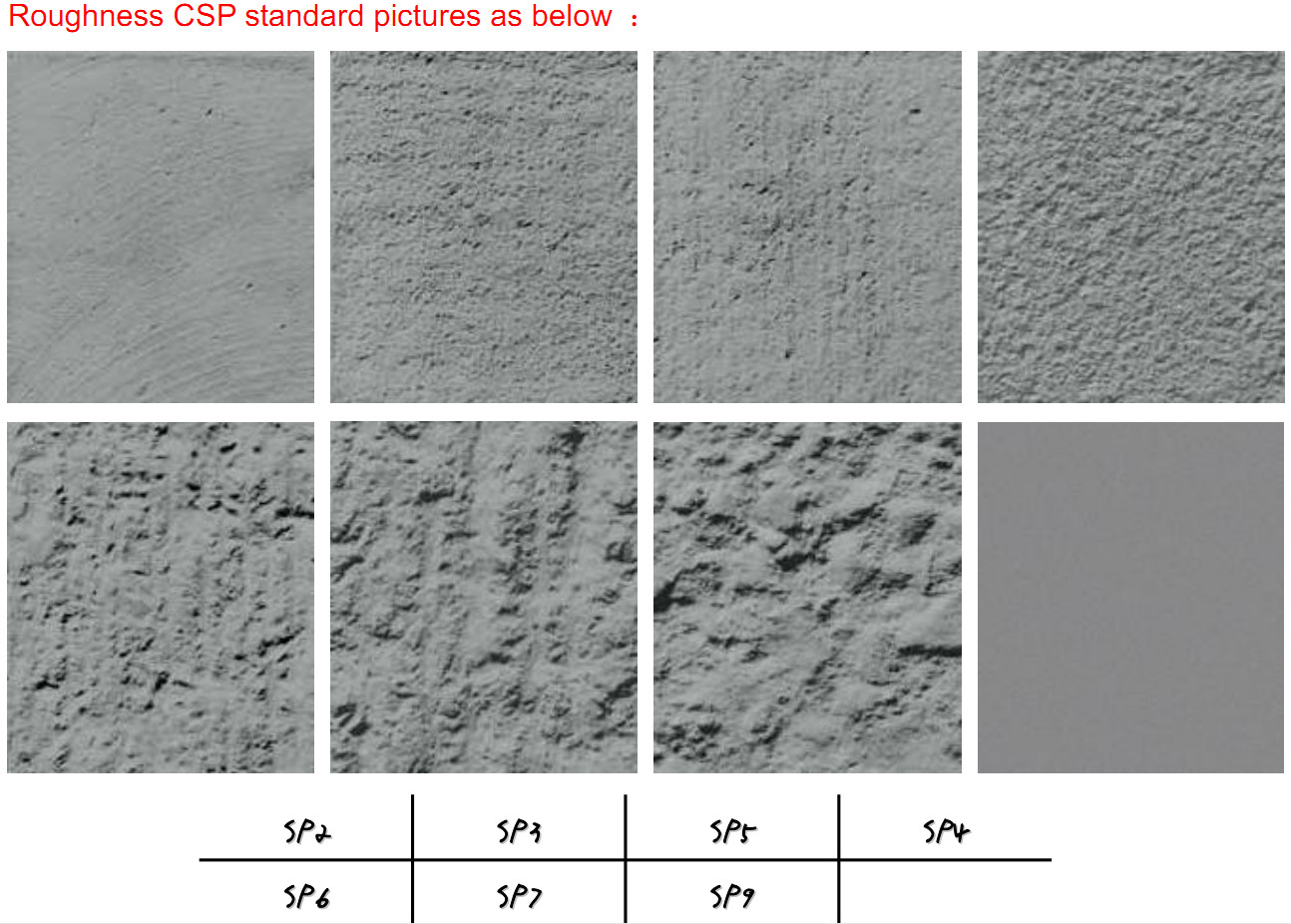

a) After cleaning the substrate,you may start mechanical shot blasting and get rid of high spot with grinding machine.The roughness of shot blasting must reach SP4. Remove the surface floating laitance,improve roughness to benefit the penetration and adhesive force of polyurethane paint. Roughness CSP standard pictures as below :

b) Process Desctription:shot blasting (sand blast) is a significant process of concrete substrate treatment. The cost is high,but it improves the adhesive force,extend the life span of floor,especially when you are installing high-cost product like Polyurethane Screed Flooring System, shot blast becomes more important. A statistics show that floors with shot blasting don’t have problem of uncoating or peeling,and the life span is at least 3 years more than floors without shot blasting.

c) Before shot blasting and grinding, there must be a clear plan for the application route and power supply connection. The voltage is 380V,and power is within 7KW.

2,Cutting Anchoring Groove:

Adopt non-dust grooving machine to cut grooves. Flip the guiding chalk line first with size of below 6M length of blocks. Special areas should given more compact cutting length according to the practical area size. After cutting clean the floor.

3,Primer Coating:

a) ALT-MF as primer to be applied by spatula. Primer with super fine aggregate can fill the anchoring grooves tightly to reach best adhesive force.

b) Find out the holes,cracks,gaps on the concrete substrate,then repair them with epoxy resin and screed.

c) The primer coating is the first coating step after substrate treatment, it is the fundamental technology. Before primer application, make sure that the substrate has met the requirement. Mix the primer strictly according to the mixing ratio; Use spatula to apply primer at consumption of 2~2.5 kg/m2, don’t leave any area without primer,don’t apply too thick of primer by one time. Check the coated floor to see if there’s any area forgotten or whitening; After application, clean the tools,close the site,put up marks of “No entry”, protect the site well.

4,Application of Polyurethane Screed Topcoat

a) Before application,make sure the weather (temperature and humidity) is ok for application.

b) Before application,check whether the doors&windows and ventilation are closed,temperature is above 15℃,and the floor is free from moisture condensation.

d) Weigh each part of Polyurethane paint precisely, stir well to prevent color aberration or wrong mixing ratio.

e) Use professional stirrer to stir well all the parts of Polyurethane paint, then carry mixture to the application site for even spreading on the floor by manual spatula,then roller of medium wool to level the paint. The consumption ranges from 7 kg/m2 to 10kg/m2,depending on the desired thickness.Control the interval time between each batch of mixed paint,make sure the application of paint reaches seamless finish.

5,Draw guide line

Follow the drawing paper,measure the position coordinates of the passage marking and guide line. Generally yellow guide line for green channel,white line for operation area.

6,Arc

ALT -600 for notch (internal corner),

Before application of screed in the internal corner,the substrate and leveling layer should have the same size of notch with larger radius.

Grind the concrete of internal corner, cut strengthening anchoring groove, then apply primer (same as floor),then mix ALT-600 with screed to apply on the internal corner area. Use ALT-600 clear resin as the final finish.

7,Notice points for Cold storage flooring:

The cold storage floor and peripheral floors must be isolated by setting expansion joint.

8,Maintenance:

Close the floor areas where the application of paint is finished, in order to prevent dust,mosquito; put up remarkable warning logo to prevent other’s people enter by mistake. During maintenance, no people walk,no vehicle run on the newly finished floor. Under 20℃ ,maintain for 5 days,Lower temperature will need longer time for maintenance.

Within 7 days after full maintenance, don’t let in other application equipment,vehicles,etc. to protect the new floor from being scratched,weight impact,damage by heavy load. Through strict and considerate protection, the whole flooring system will have its best performance in the future.

Chinese

Chinese English

English