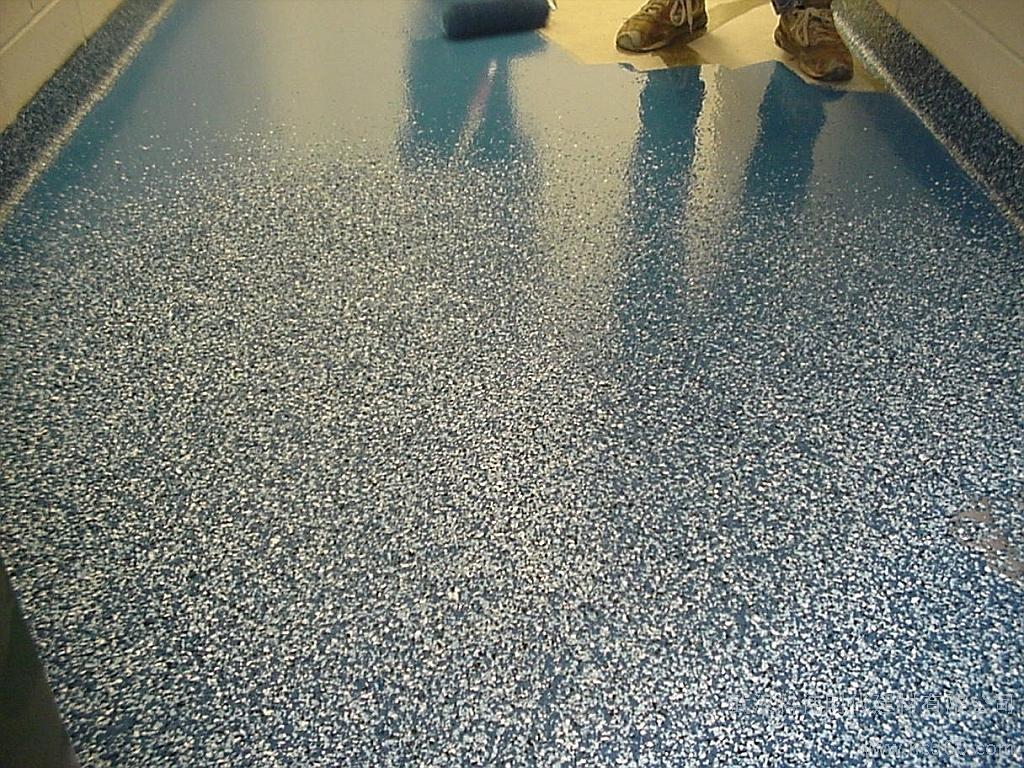

CP-6000 Epoxy Floor Paint Application Instructions

Application instructions:

1. Surface preparation:Grind the concrete floor and repair flawed area to achieve a flat concrete surface. Correct substrate preparation is critical for optimum performance. Surface should be sound, clean, dry and free from loose particles, oil, grease, and other contaminants.

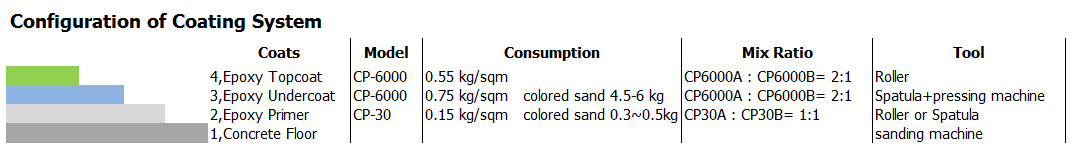

2. Primer Epoxy: Mix CP-30A and CP-30B in a barrel according to 1:1 by weight. The reference consumption is

Inspection standard for the primer: even film with certain brightness.

3. Scatter small quantity of colored sand on the primer to form a thin coat to provide adhesion for primer and undercoat.

4. Undercoat Epoxy Paint: Prepare a barrel, mix CP-6000 A and CP-6000 B based on 2:1 in it, and then add colored sand into the barrel. Usually speaking 0.75kg of CP-600 mixture and 4.5-6.0kg of colored sand. Stir completely and then apply the mixture and press it with pressing machine. (touch dry, 4 hours; hard dry, 10 hours)

5. Topcoat Epoxy Paint: Mix CP-6000A and CP-6000B based on 2:1 and then apply the mixture with roller for twice or three times. The consumption quantity is about 0.55kg/sqm.

6. Maintenance: 5-7 days. Don’t put it into use or wash with water or other chemicals.

Chinese

Chinese English

English