CP-800 Outdoor Polyurethane Floor Paint Application Instruction

Application Procedure:

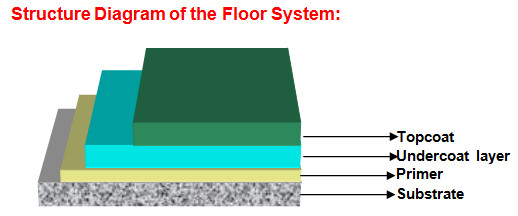

1. Surface preparation: Correct substrate preparation is critical for optimum performance. Surface should be sound, clean, dry and free from loose particles, oil, grease, and other contaminants. Sand the concrete floor with sanding machine, repair the flawed areas of floor,then clean it.

2. Epoxy Primer: Prepare a barrel, pour CP-30A and CP-30B in it based on 1:1. Stir the mixture well and then apply it with roller or trowel. The reference consumption is

Inspection standard for the primer: even film with certain brightness.

3. Epoxy Undercoat: Mix CP-MA and CP-MB based on 5:1 first, then add quartz powder (1/2 of the mixture of A and B) into the mixture, stir it well and apply with trowel. The consumption quantity of A and B is 0.5kg /sqm. You can do it one coat at one time or two coats at two times. In the second case, the application interval is about 8 hours at 25 degrees. Sand the first layer, clean it and then apply the second layer. After the whole application, wait another 8 hours, grind it, clean the sanding dust and then continue the next procedure.

Inspection standard for the undercoat: Non-sticky to hand, no softening, no nail print if you scratch the surface.

4. Polyurethane Finish: Mix CP

Inspection standard: even film, no bubbling, uniform color and scratch resistance.

Application Notes of Finish Polyurethane Paint:

Mixing: CP

Reference coverage: 0.3㎏/㎡(two coats)

Application conditions: temperature ≥

Notes:

1. The given pot life is based on

2. The application environment should be clean, dry and dustless. Control the ventilation properly during application to avoid imperfect coating performance caused by impurities.

3. The paint film will be dull and floating if the relative humidity is above 80% during application and hardening.

Storage:

Seal the can tightly and store in a cool, well-ventilated place. Avoid damp, sunlight exposure and freezing.

Finished effect:

Chinese

Chinese English

English