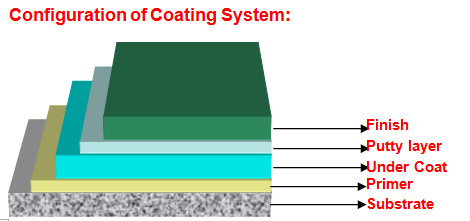

CP-1000 Solvent based epoxy floor paint application instructions

Application instructions:

1. Surface preparation:Correct substrate preparation is critical for optimum performance. Surface should be sound, clean, dry and free from loose particles, oil, grease, and other contaminants.

2. Epoxy Primer: Mix CP-30A and CP-30B in a barrel according to 1:1 by weight. The reference consumption is

Inspection standard for the primer: even film with certain brightness.

3. Epoxy Undercoat: Prepare a barrel, mix CP-30A and CP-30B according to 1:

Inspection standard for the undercoat: Non-sticky to hand, no softening, no nail print if you scratch the surface.

4. Epoxy Putty layer: Prepare a barrel, mix CP-30A and CP-30B in it according to 1:1, pour in appropriate quartz powder, stir completely and then apply the mixture directly with trowel. Wait for 12 hours, sand the coat with grinding machine, clean the dust and continue the next process.

Inspection standard for the putty layer: Non-sticky to hand, no softening, no nail print if you scratch the surface.

5. Epoxy Topcoat: Mix CP-1000A and CP-1000B according to 2:1 and then apply the mixture with roller for twice at consumption 0.3 kg/m2. The second layer must be applied after 12 hours.

6. Overcoat varnish: Apply this clear varnish over the top coat with roller. The consumption quantity is

7. Maintenance: 5-7 days. Don’t use or wash with water or other chemicals.

Clean up:

Clean tools and equipments first with paper towels, then clean the tools with solvent before the paint hardens

Finished Effect:

Chinese

Chinese English

English